When choosing a wiring system, the cost is often a key factor. Although it is not the intention of this article to suggest that the choice of a wiring system should be made only on the basis of cost, it does give information about where cable tray wiring system cost reductions will occur.

Cost Reductions in the Design Process:

As the project moves forward through the planning phase, the operational fundamentals and safety metrics are established and implemented. During the course of the planning cycle and even into the beginning stages, the necessary adjustments to fulfill the criteria are implemented. When compared with the same alternative system, the expense and amount of time required to accommodate modifications throughout the engineering and design stages are going to be much lower when a cable tray wiring system is used.

Cost Reductions in the Acquisition of Materials:

When compared to an alternative cable tray system, a cable tray wiring system has a significantly reduced number of unique components. The elimination of certain components results in cost reductions. There is a potential for cost savings of up to 80 percent when cable trays, supports, and many other products are purchased. When the overhead costs are considered, this is often contrasted to the other wiring schemes. The National Electrical Code specifies a fill capacity of 21 square inches for a ladder or vented trough cable tray that is 18 inches wide. To achieve the same fill capacity would need seven conduits measuring 3 inches in diameter.

Savings on the Cost of Installation

When compared, the amount of time needed to install cable tray systems is much less. The installation is the part of the cable tray system that offers the greatest opportunity to save a significant amount of money. In addition to this, the speed of the installation is increased. The number of components that must be present throughout the installation procedure is much lower. When compared to the installation of other types of wire systems, the procedure of installing cable systems needs far less manual labor.

Savings on the Cost of Maintenance:

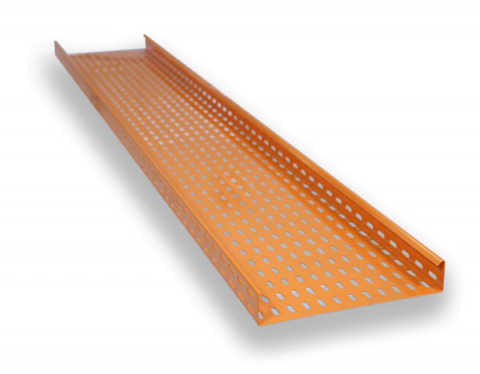

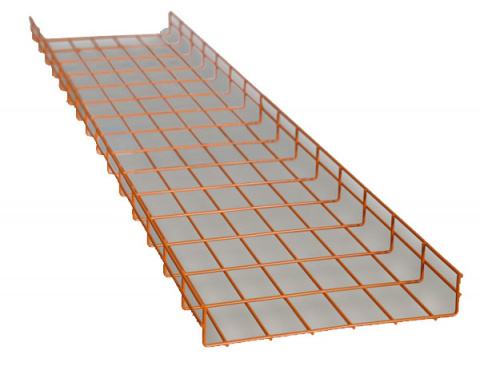

Any point along the path provides access for the cables to enter or depart the cable tray. The one-of-a-kind characteristic enables maintenance at the very lowest potential future cost. When compared to conduit wiring systems, wiring systems that use cable trays provide considerable cost savings benefits. They even offer benefits over conduit wiring systems in terms of ease, reliability, and safety. Basket, perforated, ladder, race-way, and other types of cable trays are some of the types of cable trays that Altura cable management supplier in Qatar. Altura cable tray supplier also carries a variety of sizes of cable trays.

Cutting Cost by Controlling Moistures

The use of cable tray wiring systems helps to lessen the likelihood of malfunctions in equipment caused by dampness. Conduits, as opposed to tray cables, provide an internal moisture channel, although tray cables do not. Because moisture is one of the primary reasons for breakdowns in electrical equipment and materials, this results in reduced future maintenance costs.

Cutting Cost by Limiting Fire Damage

Damage to PVC-jacketed tray cables and the cable tray is typically confined to the area of flame contact with an extension of a few feet on every side of the burned area. In certain cases, the damage may extend beyond this area. When a fire of this kind engulfs a bank of steel conduits, the steel conduits act as a heat sink, and the shielding of the conduit’s conductors is compromised over a significant distance. It’s possible that the thermoplastic insulation may melt into the steel conduit, in which case the conduit would need to be replaced over a considerable distance. This took place at a chemical facility in the state of Ohio. It was necessary to replace the rigid conduit over a distance of ninety feet. Under these circumstances, the cost to repair the fire damage caused by a conduit wiring system would typically be higher than the cost to repair fire damage caused by a cable tray wiring system.

Conclusion

ALTURA cable trays suppliers in Qatar provide a high degree of adaptability, which includes the ability to place individual sections as well as get access to cable supports. The cable trays are available in a wide range of configurations and finishes, including pre-galvanized, galvanized post-production, and epoxy coated varieties, in addition to a number of different grades of stainless steel.