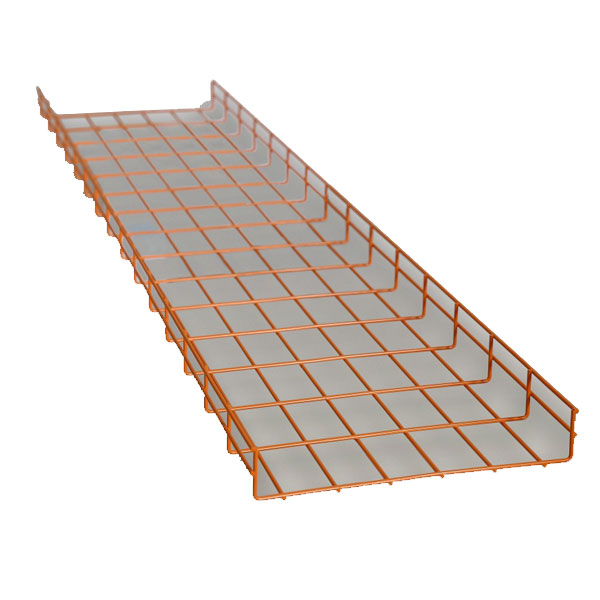

Wiring inside cable trays has the potential to produce fires, electrical hazards, and other potentially fatal incidents if improperly organised and fitted. As a designed component of a cable management system, cable trays are always used to support, channel, shield, and provide a path for cable systems. Cable trays are used in combination with wiring distribution networks for powering low wattage control, telecommunications, or other electronics.

Alturas is the premier manufacturer of Cable trays in Qatar.

If utilised properly, cable trays should make it simpler to tag, discard, and track cables. Regarding systems that might need to be improved, altered, or moved in the long term, cable trays are an excellent substitute.

During the installation, setup, maintenance and supervision of cable trays, appropriate safety measures should be put in place. A standard testing laboratory should describe or designate cable trays, the components and cables they comprise, and the wiring techniques used as appropriate for the location in which they are installed.

Importance of Cable Tray Maintenance

To ensure effective operation, cable trays must be installed in compliance with the installation guidelines. Overloading is a common problem for cable trays. It can result in a tray, its connections or supports breaking down, posing risks to those directly beneath the tray and even triggering component failure that could result in electrocution and arc-flash events whenever the cables are simply no longer secured.

Cable Safety

Since cable trays are available in a range of sizes, they may be constructed to sustain a wide range of loading arrangements; however, due to their adaptability, cable trays are especially vulnerable to overloading.

The three main elements govern the appropriate and safe loading of cable trays:

- Limitations on weight stated by the manufacturer

- Cross-sectional area restrictions result in cable fill limitations.

- Parameters for conductor spacing

When cable trays are overloaded, the tray, its connection points, or its clamps may break, creating a risk to persons underneath. If the cables are simply no longer secured, this could potentially result in electrical shocks and blast events from hardware failures. Excessive heat accumulation in and around power rails in overloaded cable trays can lead to the coating failing, raising the risk of shocks.

Things to Check

Place new cable tray arrangement above, beneath, or adjacent to a packed cable tray. Give yourself enough room to manoeuvre around the new tray. Uninstall any cables that are still in cable trays. Provisional wire installed in cable trays should be taken out after jobs are finished.

Elevated levels of flammable or explosive vapours, gases, and particles are prevalent in hazardous environments; therefore, care should be taken throughout installation to prevent generating an immediate danger. Only wire that is permitted in such situations may be included in cable trays in unsafe zones.

The following are possible ratings for cable trays:

- Locations that are corrosive and considered hazardous

- Whether placed inside or outside (to the elements)

- Places susceptible to movement and electrical noise

In addition to running laterally via wall surfaces, cable trays can be designed to run vertically across floorboards or decks. To help prevent fire hazards or combustion consequences, appropriate fire barriers should be built wherever cable trays pass across fire-rated boundaries, ceilings, and floors. Cable trays must not be placed in situations where they’ll be compromised.

Although additional safety precautions might be necessary, cables and components that are permitted for use in cable trays should be enclosed. The wire has to be de-energized if maintenance on cable tray setups could introduce workers to live components or damage the shielding. For safety measures and to avoid arcing, which can happen anywhere in the electrical installation, cable tray systems must be grounded.

Aluminium and stainless steel are the most popular examples of metallic cable trays that can be used as instrument grounding components. Only if routine monitoring and maintenance guarantee that the installed cable tray network is maintained by skilled staff are metallic cable trays permitted to be used as instrument grounding cables. The right grounding should always be carried out and validated before cables can be powered.

About Altura

ALTURA Cable trays suppliers in Qatar offer a lot of flexibility in terms of where you can place specific components and how you can get to cable supports. The cable trays are available in a range of sizes, fittings, and coatings, including pre-galvanized, post-production galvanized, epoxy coated, and with different stainless-steel grades. Our cable trays are perfectly engineered to handle cable loads and real-world site issues.