It can be a hassle to choose the right Unistrut Channel for an application. Knowing some facts and learning a few tricks will help you in that case. This article will narrate all the things in further detail that will set for selecting the right strut.

Facts to Check for Selecting a Strut Channel

Here are a few facts to check for choosing the best strut channel:

Profile Dimensions

The Unistrut P1000 channel is by far the most popular choice among our products. It is manufactured in the plant in far greater quantities, and it is significantly easier to get. Because of this, it is often the most cost-effective option and the one that is most readily available. The components and fittings that are produced for the 1-5/8-inch diameter “Additionally, there is greater availability of series. Therefore, Unistrut P1000 is often your best option if you currently have a job that you are looking to leave as soon as possible.

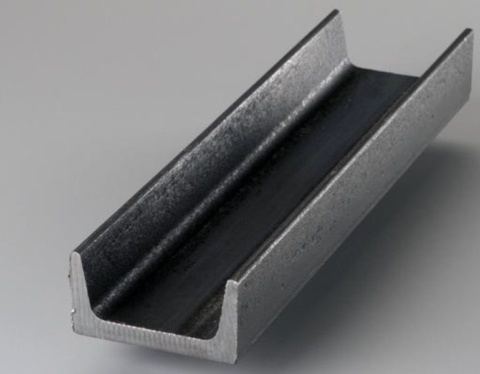

The Unistrut P1000 channel, along with the rest of the Unistrut frame members, is manufactured using a cold process from low-carbon strip steel. It has a continuous slot along one side and its edges are inturned to create an open ‘c’ shape.

Channel Length

If you want to send the channel by UPS, you’ll need to have it cut to the appropriate length first, which means you can’t ship large amounts of it unless you use a box truck or a flatbed. Packages of channels normally consist of fifty individual pieces; hence, a bundle of 10-foot lengths will include five hundred linear feet of material, while a bundle of 20-foot lengths will contain one thousand linear feet of material.

Saw cuts are normally an extra price since they are an added service. In addition, the majority of suppliers will cost you a whole length, even if you only use two 24-inch pieces of the material.

Solid or Holes

When picking between a solid Unistrut channel and one with holes or slots, it is vital to examine the intended use of the channel. Are you constructing anything, such as a shelf or rack, using it? Are you wall-mounting it or dangling it from the ceiling? If yes, how do you intend to proceed? Are bolts required via the channel?

These are issues that you should consider. If you intend to bolt anything through the channeling, you may want to explore holes or slots so you do not have to drill through it – the Unistrut channel is designed to be simple to install and does not necessitate drilling or welding!

T-shaped slots are by far our most frequent hole design. The rear side of the ‘T’ slot channel features extended slots that fit 1/2″ hardware.

The ‘HS’ type channel includes a row of round holes that take 1/2″ hardware.

‘H3’ is identical to ‘HS,’ except the channel’s perforations are situated on all three sides.

The ‘SL’ features rectangular holes that can take 3/8″ hardware.

Channel Finish

The majority of Unistrut Channel is offered in Perma-Green, Plain Carbon Steel, and Pre-Galvanized finishes. Also available are hot-dipped galvanized. Though alternative finishes may be used for soldering, plain carbon steel with a small oil coating to prevent corrosion is often the chosen ‘finish’ for welding.

Carbon steel is not suitable for use in damp or corrosive conditions or in outdoor settings. Carbon steel corrodes over time. However, it may be powder-coated, hot-dipped, or painted. Therefore, it may make sense to use it if you want to add a finish to the manufactured item after manufacturing has been done.

Perma-Green and Pre-Galvanized are the most prevalent finishes and provide adequate protection against moisture, elements, and corrosive agents.

Loading

As was discussed before, if your channel has any holes or slots, the total amount of weight that it can support will be reduced. The amount of weight that each member is able to sustain is going to be determined by the various gauges of the various Unistrut channel profiles, as well as the widths and lengths of those profiles. The Unistrut Catalog includes column and beam-loading data charts that are comprehensive for every kind of channel that is made by Unistrut. Refer to these charts, or get in touch with a Unistrut Product Engineer by going to the Unistrut website and contacting them directly.

Conclusion

Struts that are in good working order are essential to the risk-free operation of your application. Struts are not only built to provide a smooth service and guarantee that your productivity and stability are not affected, but they also act to assist minimize the early damage. If are in search of the right strut, contact Altura Industries, one of the best unistrut channel suppliers in Qatar.