C channels are one of the most popular metal channels and are frequently used in buildings as supports for walls, ceilings, roofs, and other structural elements. Since sheet metal can be roll shaped to match the specific requirements, the word “C channel” embraces a broad range of channel forms, dimensions, and sizes.

Construction firms use structural steel and aluminium a lot. It’s often used in trailers and works well as a substitute for wood in buildings. The I-beam is perhaps the most identifiable structural form. There are times when a “C” from the best C-channel steel suppliers in Qatar could be better!

But what is this C-channel steel? We explain below!

Explaining C-Channel steel

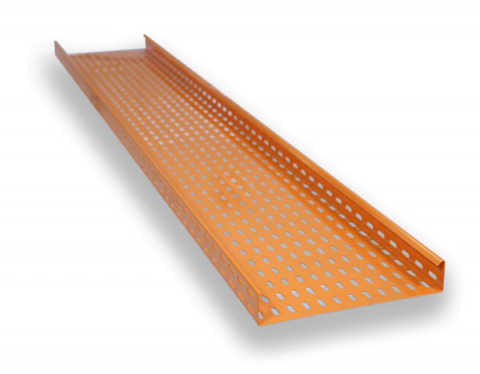

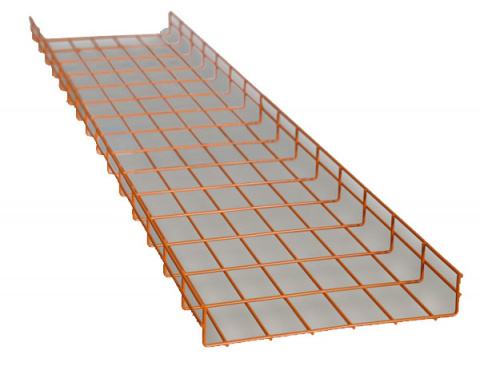

A regular production component, channel steel is typically made from hot-rolled steel. It features a broad, flat surface with right-angle flanges on both sides. C channel steel features radius corners and a noticeably angled outer border. The sturdy channel steel helps anchor things on and provide support thanks to its wide, flat surface.

The term “C channel” refers to the roll-formed metal’s profile, which replicates a C. A U-shaped channel becomes a C channel by adding flanges to its two sides. In some cases, the sides of the flanges can be crimped back to form a crimped C channel.

There are an infinite number of channels with the name “C channels” that are available in a broad range of sizes, shapes, and configurations to meet the requirements of diverse applications.

Where is C-channel steel used?

C channel steel is most frequently used to support bridge decks and other heavy machinery. I-beams & H-beams that are stiffer can break, but this steel can withstand flex and other stresses. With the C-channel steel suppliers in Qatar, you can get steel channels that come in a range of widths and diameters.

Its cross-section is shaped like a squared-off C, with two vertical branches on the top and bottom and a straight back. The structure is more durable when using C-channel steel variants that have short, inward-facing edges at the ends of the extensions. There are holes in other channel types for bolting. C channel steel is less flexible and thinner than other structural steel products.

For outdoor applications, C-channel steel is also useful. This steel is more corrosion-resistant because it contains extra quantities of nickel, copper, or chromium. It is a fantastic choice for towers, construction machinery, light poles, and many other items owing to its lightweight and resistance to corrosion. Any environmental condition is suitable for using this C-channel steel.

How is C-channel steel manufactured?

The C channel is a versatile and widely used building material, and its production process is equally impressive. Now, let us know the various steps involved in C channel manufacturing.

- Cutting the steel

The first step in manufacturing is to cut the steel into the desired shape and size. It’s made using a cutting machine designed specifically to cut steel into the desired shape and size.

- Hot-rolling the steel

In this step, the steel is heated to a high temperature to make it malleable and easier to shape. After the steel has been heated, it is cooled and shaped into the desired C channel shape.

- Coating the C-channel

The next step in the manufacturing process is to finish the C channel. It is done by sanding the steel to give it a smooth finish and then applying a protective steel coating to protect it from corrosion and other environmental factors. Once the protective coating has been applied, the C channel is ready for construction project usage.

Final Words:

C-channel steel is available in a range of sizes and thicknesses that is used in several industrial applications. Compared to I-beams and other steel components, the C-channel structure’s adaptability allows for higher manufacturing rates. The C-channel steel makes buildings lightweight and guarantees stiffness and strength for machine frames and other manufacturing applications.

The C channel is a popular and widely used building material, and its production process is equally impressive. By following the above steps, the C channel is manufactured with precision and accuracy, ensuring that it is of the highest quality and ready to be used in various construction projects.

We at Altura, specialize in high-grade steel products. Want to buy C-channel steel for your next project? Buy from Altura, the best C-channel steel suppliers in Qatar!