A cable tray is a specific kind of confinement used to provide support for sealed electrical cables employed in the power distribution, regulation, and communication processes. As a result of its ability to provide solutions that are all of these things simultaneously, cable trays have developed into an essential component of modern industrial and commercial architecture.

Types of Cable Trays

The most common kinds of cable trays are composed of steel, aluminum, or fiber-reinforced plastic (FRP), and they come in a total of 6 different types.

Ladder Cable Tray

In most cases, it is used in settings that need intermediate to lengthy support spans ranging from 12 to 30 feet. It is estimated to cover 75% of all cable tray wiring systems and equipment. Because it has so many desired functions, it is the sort of cable tray most often used.

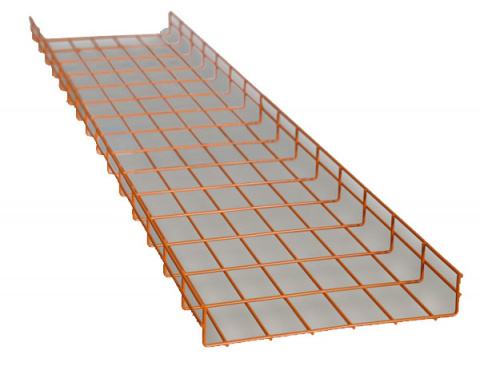

Wire Mesh Cable Trays

Wire mesh cable trays, also known as “basket cable trays,” are created by manufacturers using wires made from stainless steel and welding each wire together to form a basket. Another term for a wire mesh cable tray is “basket cable tray.” When engineers need to sustain low-voltage cables, such as those used in telecommunications, they opt for wire mesh cable trays instead of traditional ones.

Solid Bottom Cable Trays

When it comes to installing fiber-optic cables, one of the best solutions is to use cable trays with solid bottoms. They do not have vented bottoms since they have solid bottoms, but they are perfect for circumstances in which you need to eliminate cable droop. You may want to go for a solid bottom cable tray for several reasons. Still, one of the most important ones is that it shields your wires and cables from any electromagnetic interference, which may hinder their performance.

Trough Cable Tray

In general, it is used for applications that generate a moderate heat and have short to moderate support spans ranging from 5 to 12 feet. Somewhat strong airflow, together with an increased frequency of cable support provided by the bottom design, offers cable support every four inches. Materials both metallic and nonmetallic are available for use. In addition, the usual widths for this kind of cable tray are 6, 18, 24, 30, and 36 inches. The typical depths are 3, 4, 5, and 6 inches, and the normal lengths are 10, 12, 20, and 24 feet. Additionally, rung spacing is set at a distance of four inches in the center.

Channel Cable Tray

Used in situations when the conduit would not be ideal, such as in installations with a small number of tray cables. The support frequency ranges from short to medium and spans between 5 and 10 feet.

Channel cable trays are the best answer for supporting wire systems with smaller dimensions. Channel cable trays, available in 3, 4, and 6 inches widths, are a discreet and visually beautiful solution to the problem of securing and protecting wires while keeping them out of reach.

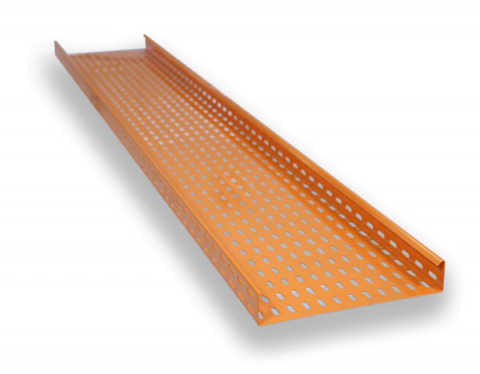

Perforated Cable Trays

Compared to ladder cable trays, ventilated cable trays provide sturdier support for cables since they include rails on either side and a vented base. The use of perforated cable trays is another option that producers of cable trays recommend. A single component is used to create perforated cable trays, which may have either a vented or solid bottom.

The majority of their applications involve power and control lines. Consequently, they are offered in three different weight capacities—light, medium, and heavy—to cater to various requirements, including those of the customer and the working environment.

Conclusion

It is crucial to become aware of the many kinds of cable trays, connectors, and materials available since this knowledge will assist you in selecting a cable tray that is appropriate for your project. Choose Altura Industries if you are seeking an experienced component vendor in the field of plant engineering from which you can get exceptionally high-quality cable trays. Thanks to our extensive knowledge and high-quality supplies, they can assist you in finishing your project quickly and effectively. In addition, you may get the appropriate cable tray for your project by going to Pro Support Solutions, where you can find further information.