It could be challenging to choose the support system that is ideal for your business given the variety of options present. There seem to be a number of key differences between the cable ladders and cable trays. Altura Industries provides you key information that should help make your decision simpler.

Find out which benefits cable trays and ladders provide to understand which meets your demands by reading this comprehensive article.

What are Cable Ladders?

In most cases, cable ladders are chosen to hold heavy or massive volumes of cabling, particularly when there are wide gaps between support systems.

Tubing and instrumentation are two most frequently supported by light-weight cables in most cable trays.

The purpose of cable ladder and cable tray systems is to serve as cable reinforcements rather than as walled-in spaces that provide conventional mechanical safety. These are not intended to be used as ladders, pathways, or seating for people because doing so could result in personal danger as well as damage to the structure and any installed wires.

What are Cable Trays?

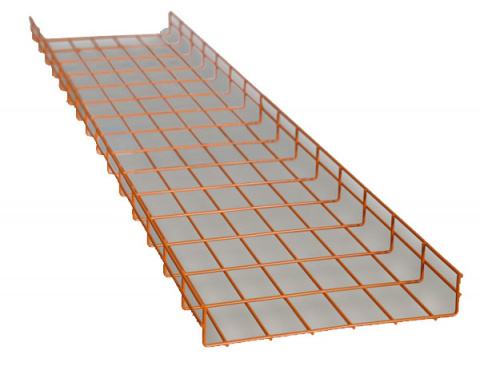

Ladder Cable Trays are designed to be used as a control cable organization or cable impact. They have two longitudinal side frames connected by particular cross over structures. Robust covers for ladder and ventilated trays are sometimes used to protect cables from debris, moisture, and falling objects.

A crested design may be used on tray lids for use either outdoors or in dusty environments to shed debris, notably grease. When a substantial majority of tiny cables are used, such as for phone or organization cables, lightweight cable trays are preferable. The “cable basket” method of manufacturing these trays is another option. Alternatively, these trays are sometimes designed as a single central spine (rail) with ribs supporting the cable on either one or both sides.

Alturas Does it Better

Alturas is the premier cable tray supplier in Qatar and cable ladder supplier in Qatar, trying to provide well-fabricated Ladder Type Cable Trays constructed of the finest steel. Their products are employed by multiple industries for the application of force throughout the building process. Their cables are evenly spaced apart and have two longitudinal side rails or rungs that are occasionally darted or soldered to the side rails. The most severe circulation is provided by this type of cable tray for warm-delivery cables like tension cables.

Benefits of Cable Tray

- Simple construction with side rails and connecting rungs. The ventilated rungs make it simple to attach cable cleats or cable ties immediately to the ladder.

- Suitable for cables used in instruments, telecommunications, and electricity.

- Can sustain pipelines, cable packages, and heavy cables over a lengthy bearing plate.

- Throughout the entire span, cables are able to enter and exit.

- Ladders offer open air flow, which is necessary to prevent cable heating.

- minimum moisture, debris, or water buildup.

- Since cables are uncovered and simple to reach, maintenance and future adjustments are not difficult.

- To safeguard cabling from UV rays, ice and snow and vandalism, shields can be installed.

Benefits of Cable tray

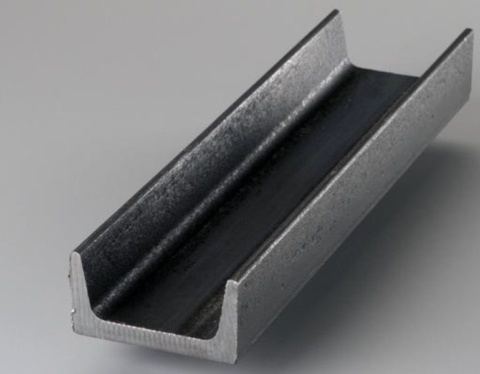

- Comprises just one metal sheet. Slot patterns are common in cable trays, making it simple to situate machinery and install cords and other fasteners like tubing clamps.

- suitable for small cables and tubes used in electrical and instrumentation systems.

- The aeration and water drainage are made possible by the holes on the bottom, which also aids in minimizing electromagnetic interference.

- Trays add extra stability and stop wires from sagging, which might impair the functionality of the circuitry.

- The solution with the best aesthetics is cable trays. Cable trays are a fantastic way to keep cables arranged and hidden in structures without paneled ceilings.

- To prevent cabling from UV rays, snow and ice, and vandalism, shields can be installed.

Alura Industries specializes in providing robustly built Ladder Type Cable Trays made of the finest steel. These are employed by various businesses to distribute force around the building. Most cables are evenly spaced apart and have two longitudinal side rails or rungs, which are occasionally dashed or bonded to the handrails. The most severe ventilation is provided by this type of cable tray for warm-delivery cables like force cables.

Ladder trays are pre-built metal structures with two side rails connected by tiers or separate cross-over bridges. The most popular and effective type of plating, ladder trays also provide the most airflow for cabling.

A cable tray system is used in the power lines of buildings to assist safeguard the electrical cables that are used for power distribution, management, and communication.