Mechanical, electrical, and plumbing engineering is abbreviated as MEP. The mechanisms that make constructions hospitable for humans are covered by any of these three technical areas. Because of the high level of engagement among MEP installations, they are generally designed collaboratively. This systematic approach also eliminates component clashes, which are prevalent whenever mechanical, electrical, and plumbing systems operate separately.

Partnering with a competent MEP engineering firm that uses cable ladders housing has a number of benefits: engineers can optimize resource requirements to lower assembly costs while maintaining enhanced stability and code compliance.

Bear in mind that there are other criteria to consider. The Qatari Energy Conservation Standard, for instance, provides standards that apply to all MEP systems and must be followed by any system that utilizes combustion equipment.

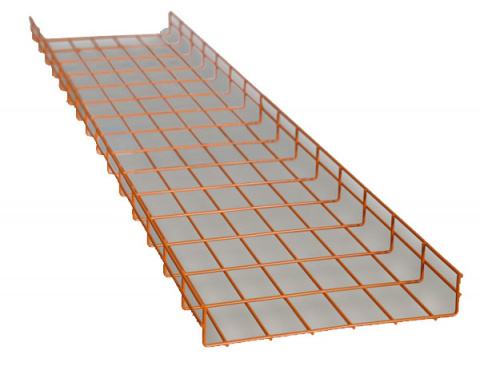

Cable ladders are designed to make it simple and straightforward to move the cable from one location to another. In buildings with a wide range of mechanical systems, cable ladders are utilized. Nevertheless, HVAC (thermal heating, ventilation, and air-con) systems account for the majority of mechanical designs in homes and offices.

These systems manage the indoor humidity and temperature to a comfortable and healthy level. Mechanical ventilation also ensures a steady flow of fresh air, ensuring that contaminants are kept to a minimum.

When device capacity is enough, mechanical setups perform at their optimum. Overengineering, in contrast to the common perception, has numerous detrimental repercussions. Excessive cooling systems and furnaces, for instance, have a tendency to cycle quickly, generating faster deterioration and internal temperature changes. Poor regulation of ambient moisture content is another result of overengineering in mechanical components.

What Are the Advantages of a Structured Cable Ladder Design?

The whole framework of all cables and related gear is known as structured cable design. This model offers a full communications infrastructure solution for a construction process. This type of infrastructure can be used for a wide range of applications. These include, and are not restricted to, data transmission through a computer network or the use of cellular service. The network as a whole should not be dependent on the access points connected to it.

The Characteristics of Structured Cabling Design

Every structured cabling system is unique. Differences occur as a result of:

- The installation’s setting has been architecturally structured.

- Elements connected by cable

- The installation’s operational performance

- Types of machinery that the installation can accommodate now or long term

- Configuration of any existing deployed system, whether upgraded or retrofitted

- the client’s specifications; and

- Manufacturer’s return policies

The methods utilized to complete and maintain cabling installations are very common. Because highly complicated setups are possible of satisfying the system’s reasonable performance, this uniformity of all installations is extremely important.

Highly Customized Design

Altura is one of the top cable Ladder suppliers in Qatar and recognizes that each structured cabling system is important due to variances in cables and couplings, instrument kinds, and architectural structure. We make sure that all of your operation’s needs are completed while maintaining a laser-like focus on your goals.

- Assurance of Quality

We specialize in giving solutions to clients that not only increase your project’s productivity levels and moreover enhance its long-term performance.

- Fully Integrated Design

Altura ensures that your requirements are fulfilled all of the code’s standards in order to achieve the best potential outcome from a fully integrated design.

- MEP Design Adds Value

When it comes to planning structural components, a unified MEP approach outperforms developing each system separately. Whenever the schematic design is separated, it’s hard to manage interaction across building systems, and hardware position clashes are very common.

Modern engineering companies hire automation to accelerate the design process owing to the difficulty of MEP system configurations. A computer automates simple and laborious procedures, allowing MEP experts to concentrate on creating the best design selections possible.

The relevance of the 3D model created during the design stage transcends further than the building project when contemporary MEP software is employed. The simulation is often used as a baseline for repair jobs, and it can be revised in tandem with major improvements to the structure.

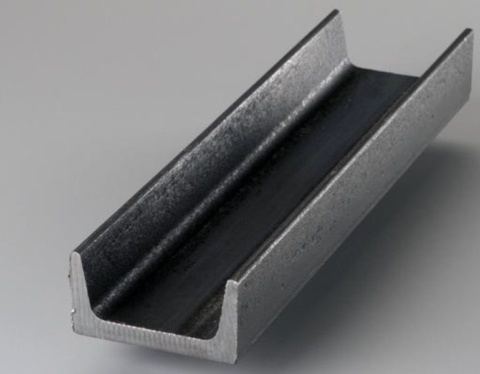

Alturas has created the greatest cable ladders by considering cable loads as well as realistic site issues. Even with wider ladders, the rungs are heavy-duty strut channels that offer strong support for the cables. By fastening rungs at the lowest point of side rails, Altura Cable Ladders have the largest cable load-carrying depth. The rung spacings are designed to allow for the lowering of any large diameter wires.