Have you ever heard of steel channels? It is a typical steel product used in the construction of buildings, used to sustain the building in all ways.

Steel channels offer structural support and are used in various structures, including walls, rafters, door frames, enclosures, and hardwood beams. Due to the enhanced capacity for impact absorption and physical support, its design is suited for different big and small-scale constructions.

But what are the types of channels found in the steel industry & what are they used for? Read to learn more!

What are steel channels?

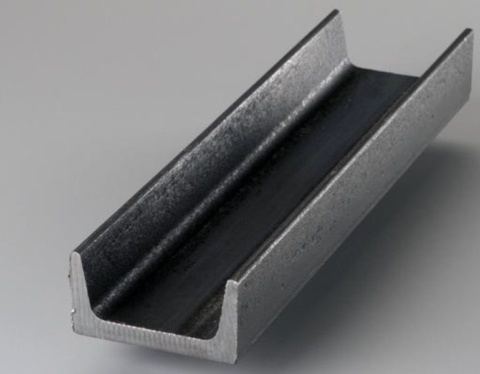

Steel channels are commonly known as “C”-type hot-rolled carbon-based steel plates with the corners of inner radius over the top & bottom regions of horizontal flanges. Two flanges that can be parallel or tapered & a broad web make up steel channels. Steel is a great material to implement while building metal channels because of its strength and longevity.

Due to its structural strength, it is used to create braces and frames for buildings as well as supports for various machines and large pieces of machinery.

When utilised horizontally, steel channels can also be used as a connecting element or an attachment. Unless an extremely significant external force is exerted, the Steel Channels—which are incredibly strong—remain unattached.

Types of steel channels used

Depending on its viewpoint, the steel channel has been divided into C and U varieties. However, there are other types as well.

- C Channel: C channels are one of the most popular styles of metal channels and are frequently used in buildings as supports for walls, ceilings, roofs, and other structural elements.

- Hat Channels: This channel has legs that are folded outward, giving it the impression of an antique man’s hat.

- U Channel: Two right angles are made on a flat piece of metal that has been rolled to give it the unique shape of U channels or slotted channels. Like other metal channels, U-shaped channels come in a broad range of sizes and shapes with flat or rounded bottoms and sides that range in thickness from a few inches to several inches.

- J Channels: A J channel is configured by making one of the channel’s sides longer than the other, which results in a profile that resembles the letter J.

- Hemmed Channels: The highest point of the leg is folded in this type of channel, creating a twofold thickness.

Slotted Channels – What are they?

The slotted channel often referred to as a strut channel, is a metal bracket used to support ducting. The slotted channel frame features a metal base with holes that work on any surface, including steel, concrete, walls, ceilings, and floors. It is accomplished using strut-specific fasteners and slotted channel accessories in Qatar, such as Z- or U-shaped fittings & bolts.

The slotted metal channel’s key benefit is that it makes it simple and quick to connect different components. They can be implemented in various circumstances because they are available in multiple lengths and sizes. Slotted channels are quite adaptable & simple to change how they are installed.

What are the slotted channels used for?

Steel slotted channels offer minimal structural support intended for usage in the electrical and construction sectors. But what else are they used for?

- Parts of appliances: They frequently serve as supports for plumbing and wiring, but they may also hold up the mechanical parts of bigger appliances.

- Assemble channel support system: U-shaped slotted steel channels and fittings are frequently used to assemble channel support systems. It results in robust metal structures that can easily support equipment such as panel boxes, wires, and electrical conduits.

- In light construction: It’s a highly adaptable light construction support product that, because of the range of fittings, styles, and sizes of channel bracketry can be used in many ways.

- As a permanent structure: They can be used either permanently to build a structure that supports wiring around a property or momentarily to store machinery and cables for short-term projects.

Wrapping up

The main benefit of using slotted channels in construction is the variety of possibilities for quickly and simply joining lengths together and attaching other objects to the strut channel using specialised fasteners and bolts designed specifically for struts. They need few tools for assembly and just modestly skilled workers, which drastically reduces the costs in many applications.

In need of slotted channels? Reach out to Altura, the best slotted channel suppliers in Qatar. Our selection has everything you want! Contact us today.